Thermo-Mechanical Analysis of a RF LINAC Cavity using CFD and FEA

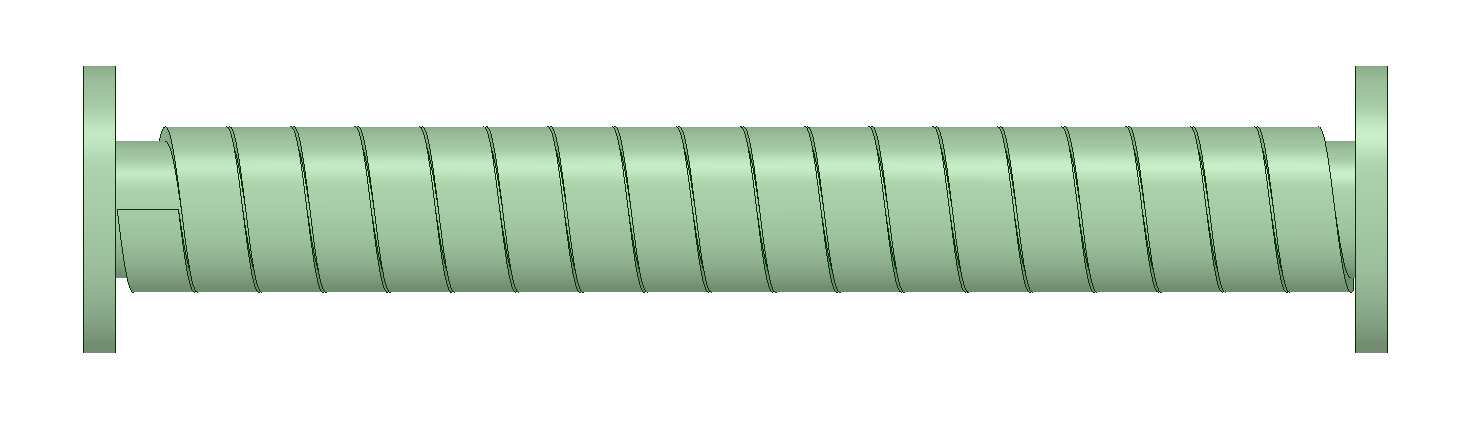

3D Model of the 17-cell OFHC Copper LINAC Cavity with Cooling Channels

Problem Statement

The performance of RF Linear Accelerator (LINAC) cavities is critically affected by RF-pulsed heating, which induces structural deformation and frequency shift, limiting the maximum accelerating gradient. This project aimed to optimize the thermal and structural performance of a 17-cell Oxygen-Free High Conductivity (OFHC) copper LINAC cavity by analyzing the impact of varying heat loads and cooling water flow rates, enhancing frequency stability and overall accelerator efficiency.

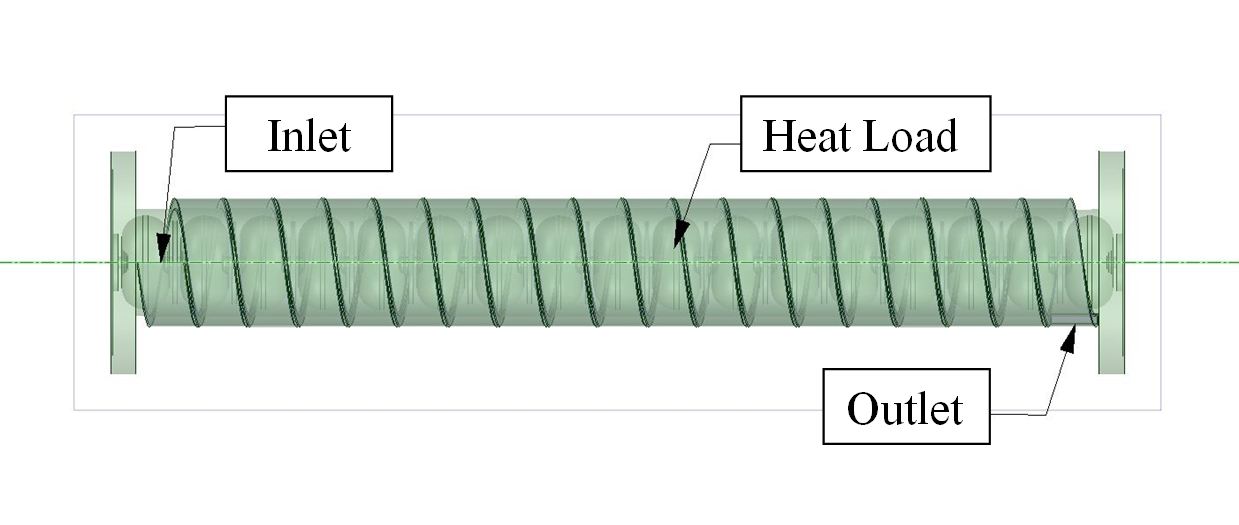

3D model of the LINAC displaying cells and water jacket

My Role

Team Leader & Project Manager

- Oversaw the entire project lifecycle

- Coordinated efforts among simulation and design sub-teams

- Ensured timely delivery of project milestones

Simulation Engineer

- Conducted advanced thermal and structural simulations

- Validated energy balance across the system

- Quantified effects of thermal loading on frequency shift using ANSYS

Tools & Skills Used

Software

- ANSYS Fluent - Computational Fluid Dynamics

- ANSYS Mechanical - Finite Element Analysis

- SolidWorks - CAD Modeling

Technical Skills

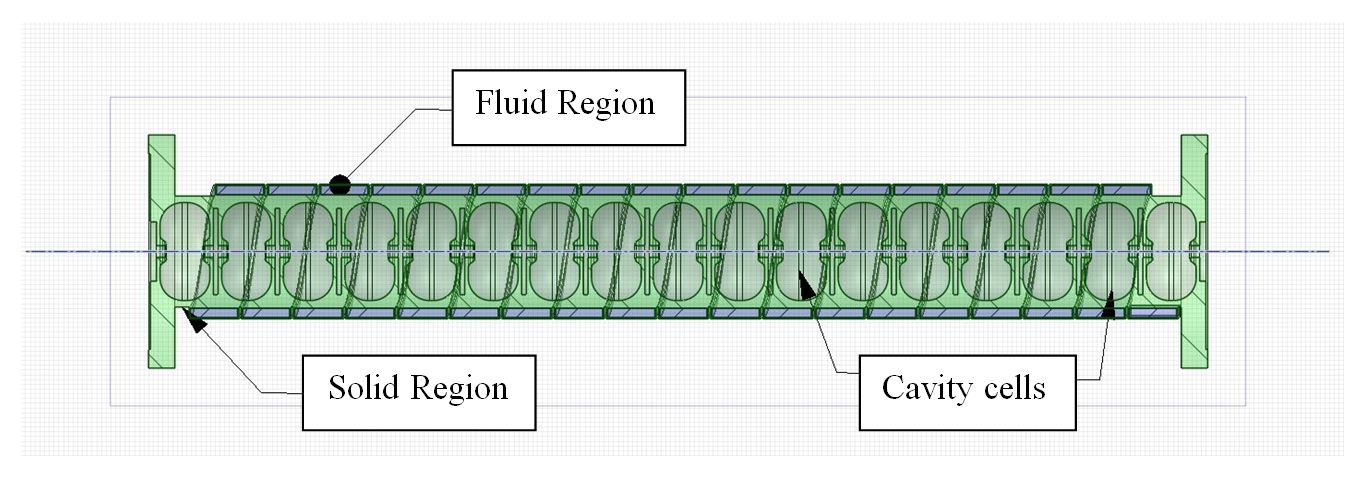

- Conjugate Heat Transfer Modeling

- Fluid-Structure Interaction (FSI) using partitioned approach

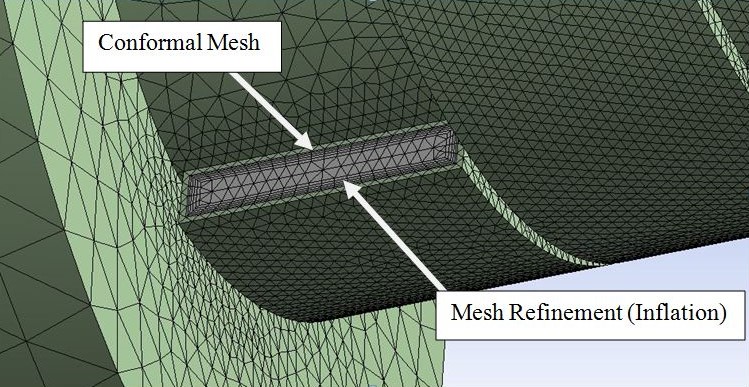

- Mesh quality optimization and boundary condition setup

- Parametric studies and result interpretation

- Frequency shift analysis using empirical relations

Advanced mesh refinement at the solid-liquid interface

Design & Engineering Process

1. Problem Formulation

Defined key performance metrics for the cavity optimization:

- Temperature distribution across the cavity

- Stress and strain profiles under thermal load

- Structural deformation patterns

- Resulting frequency shift during operation

2. Model Setup

Built a 3D model of a 17-cell LINAC cavity with helical water cooling channels designed to efficiently extract heat.

3D model of the cavity showing computational domain

3. Thermal Analysis (CFD)

Using ANSYS Fluent, we simulated:

- RF-induced heat loads ranging from 0.8 kW to 1.8 kW

- Water flow rates varying between 15 LPM and 35 LPM

- Temperature distribution patterns across all cavity cells

The analysis revealed a linear temperature rise with increasing heat load and an exponential decay pattern with increased cooling flow rate.

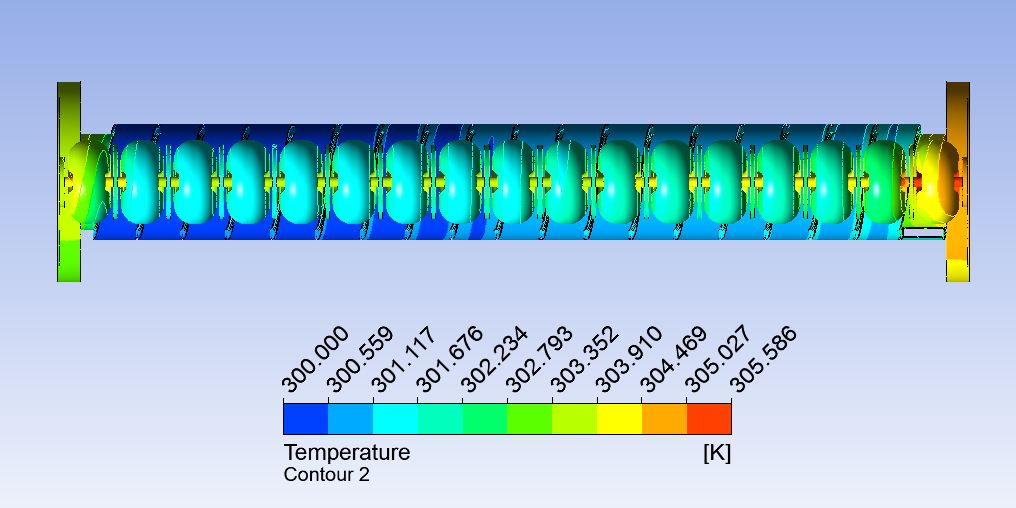

Temperature distribution for 1.8 kW heat load and 23 LPM water flow rate

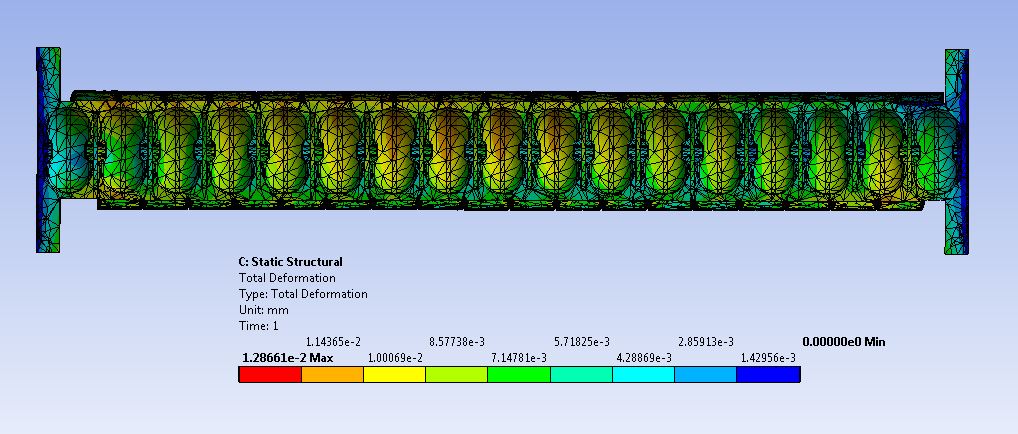

4. Structural Analysis (FEA)

Using ANSYS Mechanical, we:

- Imported temperature profiles from the CFD analysis

- Computed resulting stress, strain, and deformation patterns

- Validated that all values remained below the yield limits of OFHC copper

Total deformation for 1.8 kW heat load and 23 LPM water flow rate

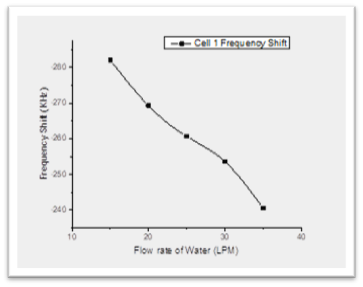

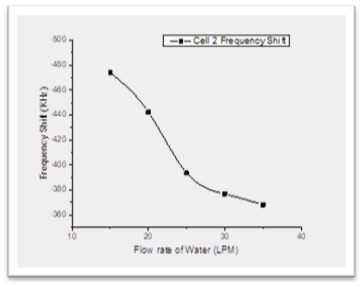

5. Frequency Shift Estimation

To complete the optimization analysis:

- Calculated node-to-node displacements from the structural analysis

- Applied empirical geometry sensitivity coefficients to evaluate frequency shifts

- Found significant shift reduction with increased coolant flow

Graph showing frequency shift reduction with increasing flow rates for cell 1

Graph comparing frequency shift across different heat loads for cell 2

Results & Outcome

Temperature Gradient

Temperature gradient across the linear accelerator inside the cavities is studied for varying flow rates of water at different heat loads.

Structural Safety

Maximum stress (89 MPa) remained well below OFHC copper's yield strength (~206 MPa), ensuring safe operation even under peak load conditions.

Performance Gain

Frequency shift was reduced by over 15% by increasing water flow from 15 to 35 LPM, enabling higher achievable accelerating gradients.

Validation

Energy balance between input heat load and simulated heat extracted by water showed less than 2% deviation, ensuring simulation accuracy.

Recognition

This work was presented at the 24th National and 2nd International ISHMT-ASTFE Heat and Mass Transfer Conference (IHMTC-2017) held at BITS Pilani, Hyderabad.

Presenting research findings at IHMTC-2017

Publication: Read the full conference paper