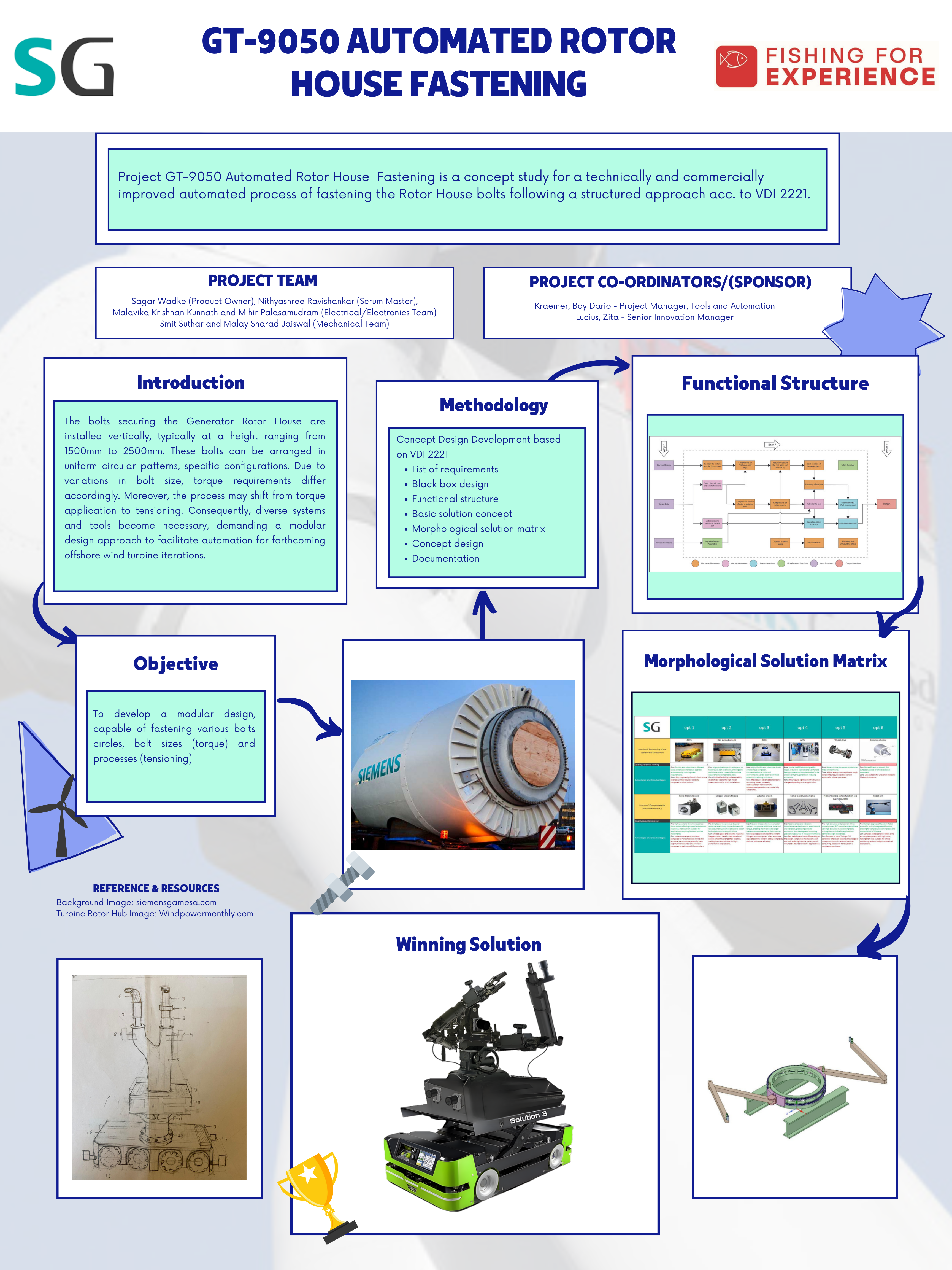

GT-9050: Automated Rotor House Fastening

Conceptual prototype of the automated fastening system for offshore wind turbine rotor houses

Problem Statement

The traditional bolt fastening and tensioning process in generator rotor houses is labor-intensive, varied, and poses ergonomic challenges due to the vertical orientation and high-torque requirements. As offshore wind turbine designs evolve, a scalable, automated solution is needed to handle diverse bolt configurations and torque specifications efficiently and reliably.

Rotor House of offshore wind turbines. Source: Google Images

Objective

To design a modular, automated system capable of handling varying bolt circle arrangements, bolt sizes (torque levels), and tensioning requirements for rotor houses in offshore wind turbines.

Team Members

Project Sponsors

My Role

Product Owner

I led the project execution and concept development, taking responsibility for:

- Coordinating cross-functional efforts between mechanical and electrical teams

- Ensuring alignment with VDI 2221 and VDI 2206 engineering standards

- Facilitating Agile workflows and sprint planning

- Acting as the primary point of contact for project sponsors and stakeholders

- Overseeing quality control and documentation

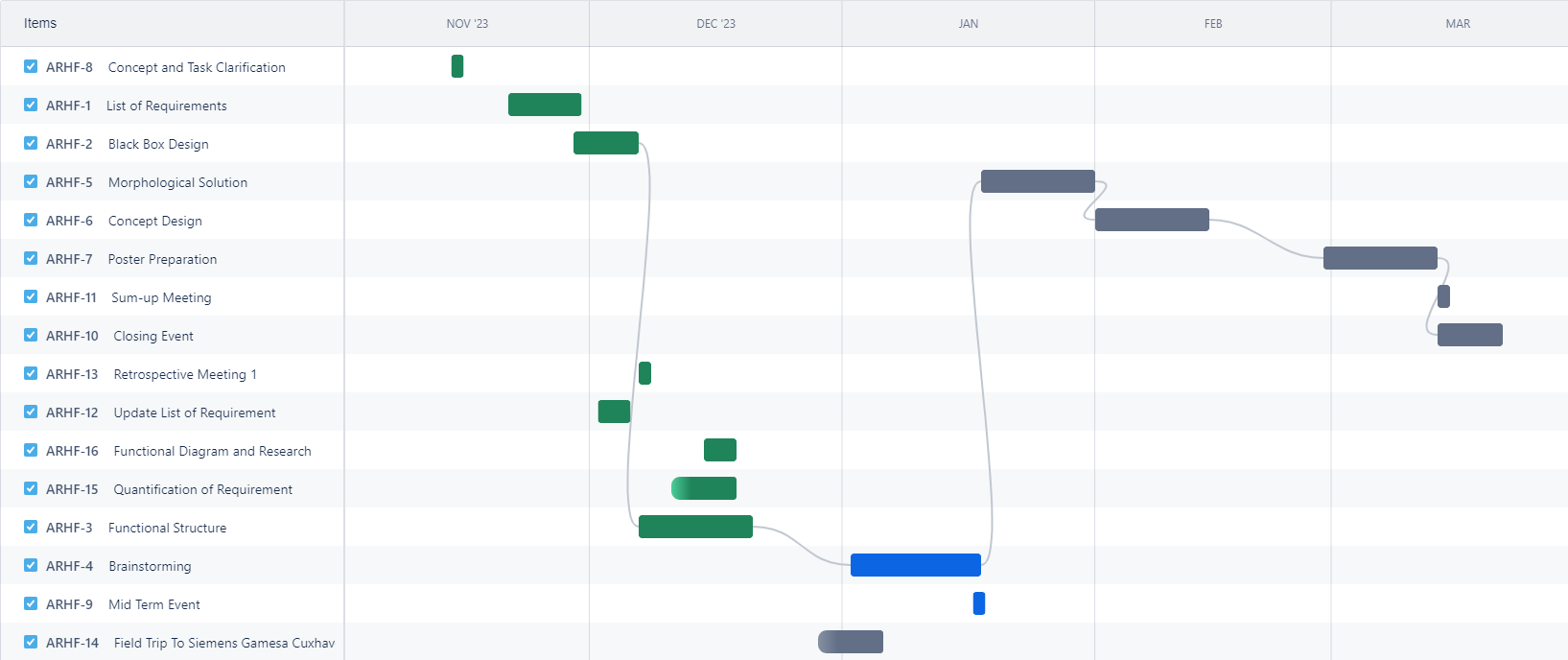

Project Gant Chart

Tools & Skills Used

Methodologies & Standards

- Agile methodology (Scrum) - Iterative development approach

- VDI 2221 - Systematic approach to product development

- VDI 2206 - V-model for mechatronic systems

Tools & Techniques

- Jira - Project management platforms

- Morphological Matrix - Concept generation

- Black Box Modeling - System abstraction

- Decision Matrices - Concept evaluation with quality parameters

Design & Engineering Process

Following the V-model (VDI 2206) and VDI 2221 methodology, we systematically approached the design challenge:

1. Requirements Engineering

Compiled comprehensive technical specifications and user needs, including:

- Bolt sizes and torque specifications for different turbine models

- Ergonomic considerations for system operation

- Environmental constraints for offshore deployment

- Safety requirements for automated high-torque operations

- Adaptability needs for evolving turbine designs

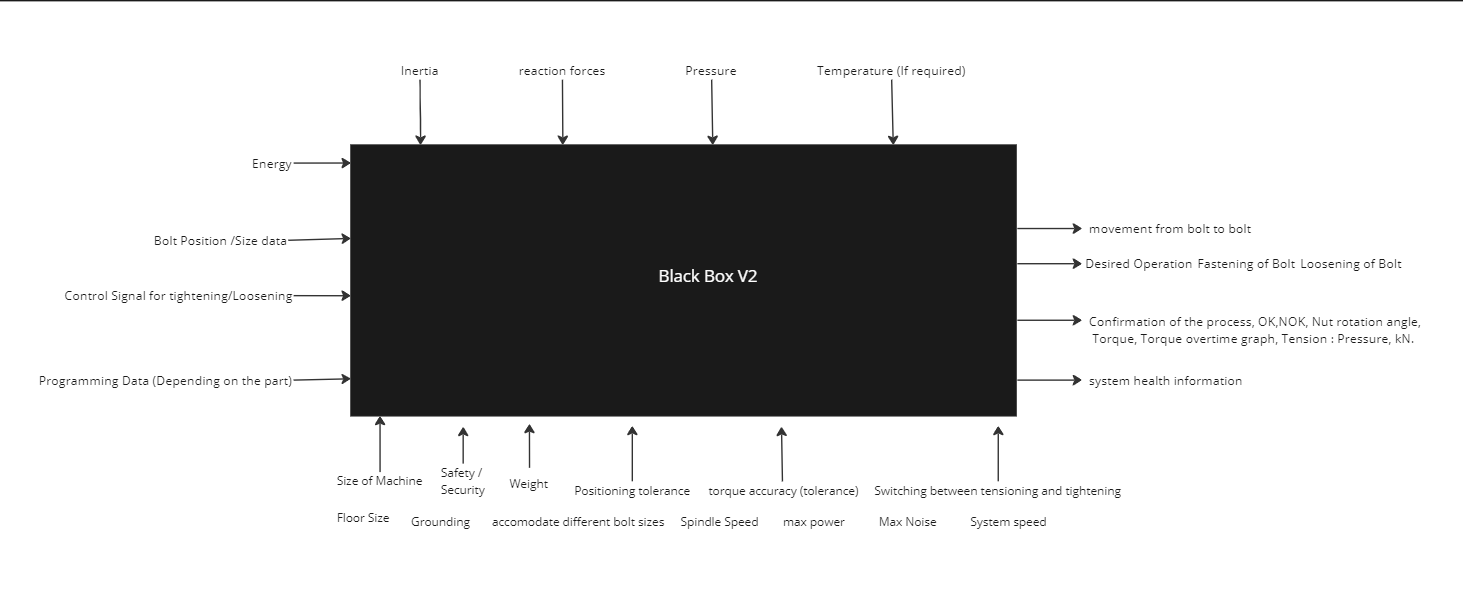

2. Black Box Modeling

Created system abstraction to analyze input/output relationships, defining:

- Energy flows (electrical, mechanical)

- Material interfaces (fasteners, rotor house)

- Signal processing requirements

- Information flows between subsystems

Black box system model showing inputs, processes, and outputs

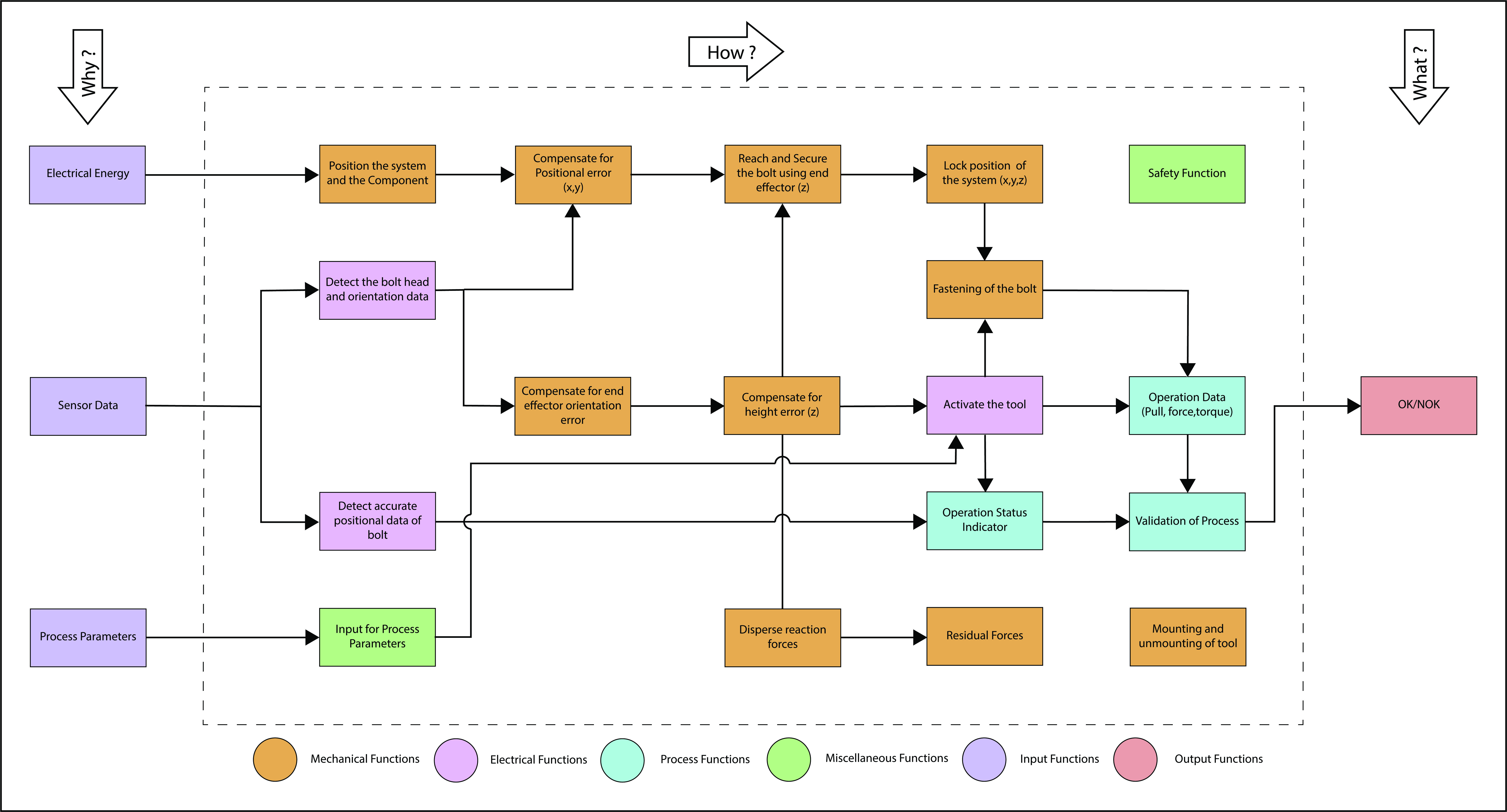

3. Functional Decomposition

Broke down the system into core functional modules:

- Positioning System - Locates bolts in various configurations

- Fastening Mechanism - Applies appropriate torque

- Control System - Manages operation sequences

- Sensing & Feedback - Monitors fastening quality

- Interface & Adaptability - Handles different bolt patterns

Functional breakdown of the automated fastening system

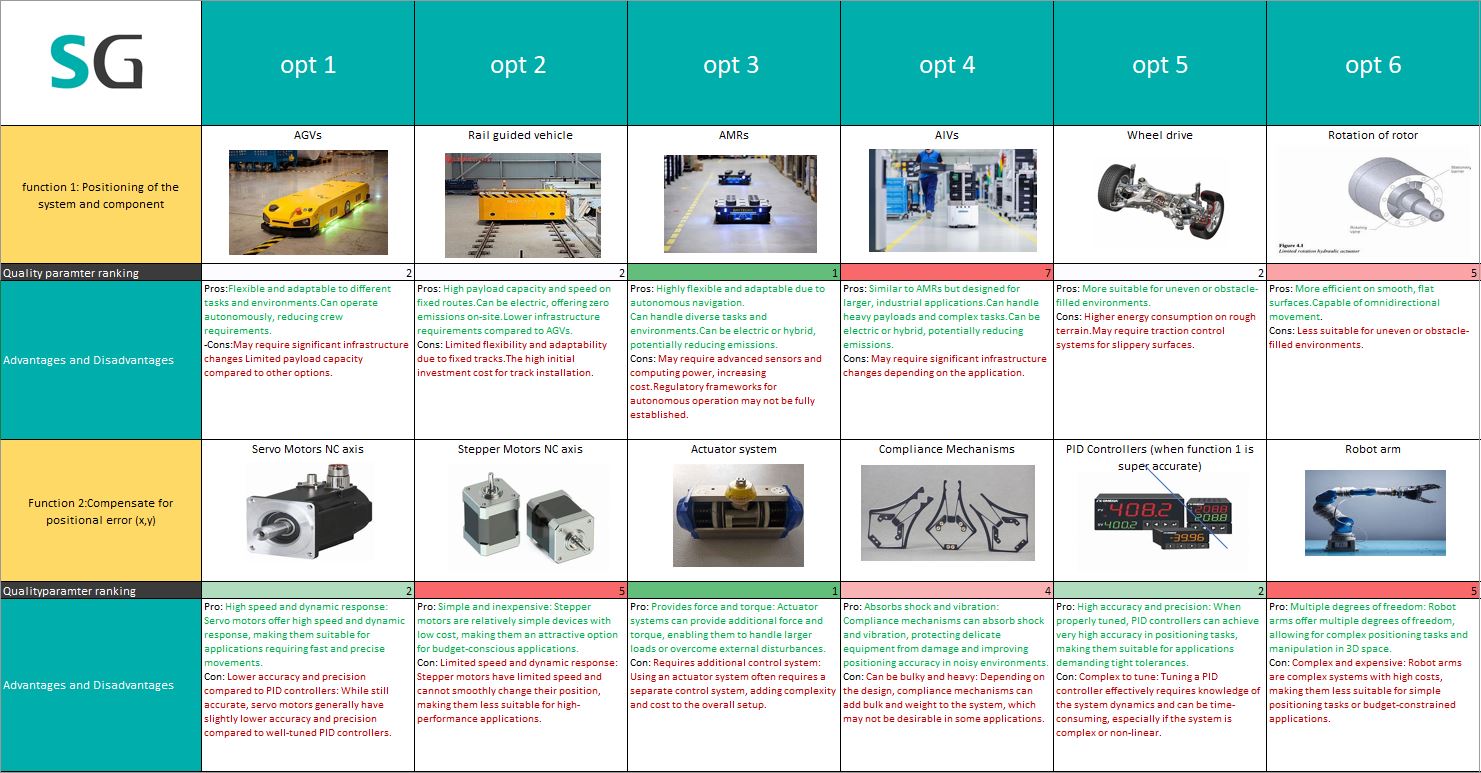

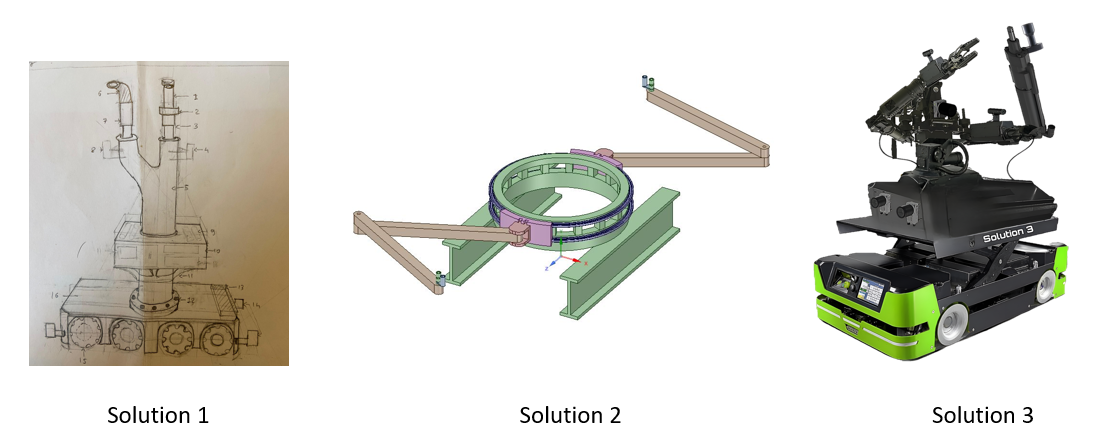

4. Concept Generation

Utilized a morphological matrix approach to explore solution combinations for each functional module, generating diverse concepts for:

- Fastening technologies (hydraulic, electric, pneumatic)

- Positioning mechanisms (robotic arm, gantry system, turntable)

- Sensing approaches (torque feedback, vision systems, load cells)

- Modular adaptability strategies

Morphological matrix showing different solution combinations

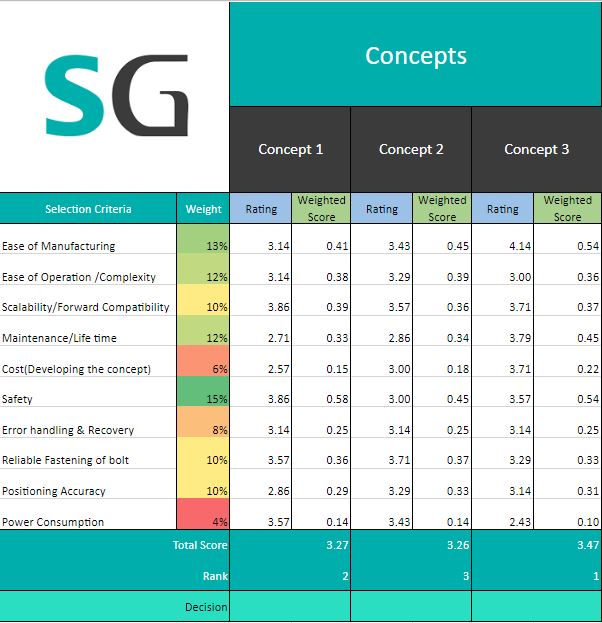

5. Concept Evaluation

Applied a decision matrix with weighted quality metrics including:

- Technical feasibility

- Adaptability to various bolt patterns

- Cost-effectiveness

- Ease of deployment

- Safety considerations

- Maintainability

Decision matrix comparing different automation concepts

6. Concept Solution

Selected and refined the optimal modular concept based on evaluation results, focusing on:

- Modular design approach for maximum adaptability

- Integration of sensing and feedback mechanisms

- User interface for system operation and monitoring

- Safety protocols for automated high-torque operations

Concept solutions for the automated fastening system

7. Presentation & Documentation

Created comprehensive documentation and presented the final concept through:

- Technical documentation package

- Professional poster presentation

- Stakeholder briefing sessions

- Implementation roadmap

Final poster presentation showcasing the automated fastening concept

Results & Outcome

Concept Design

Delivered a detailed, scalable concept design for automated rotor house fastening and tensioning that addresses the core challenges identified.

Modularity

The winning solution featured a modular architecture capable of accommodating various bolt sizes and patterns, future-proofing the system for evolving turbine designs.

Stakeholder Feedback

Received positive feedback from project sponsors during the final presentation, validating the approach and solution.

Future Impact

The project serves as a foundational concept for future automation efforts in offshore turbine maintenance, potentially reducing labor costs and improving reliability.

Team behind the automation concept project